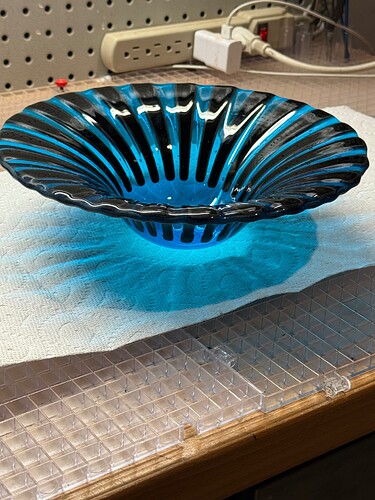

Realized you get devit on all glass edges where wazer cuts so will use a lap grinder on edges going forward. Devit on the sides of the black rays actually looks cool on the project. First firing in new kiln, first wazer project. Glass is actually Deep turquoise but doesn’t show in pics. Any advice on dealing with devit on exposed edges appreciated. 11 inch diameter so fairly large.

1 Like

There are diamond hand pads, different abrasive to fine so the edges can be sanded. They knock off the sharp edges and probably would clean off the glass and not take of alot of glass. I got mine from delphi glass, but there are other places. They last a long time.

Thanks, I have those. I think it was just a learning curve-if you aren’t butting pieces together before fusing you have to apply devit to all of the edges that are exposed. Live and learn ![]() Any edges the wazer cuts need devit unless they are nested against another piece.

Any edges the wazer cuts need devit unless they are nested against another piece.